60 years of the Hotlab

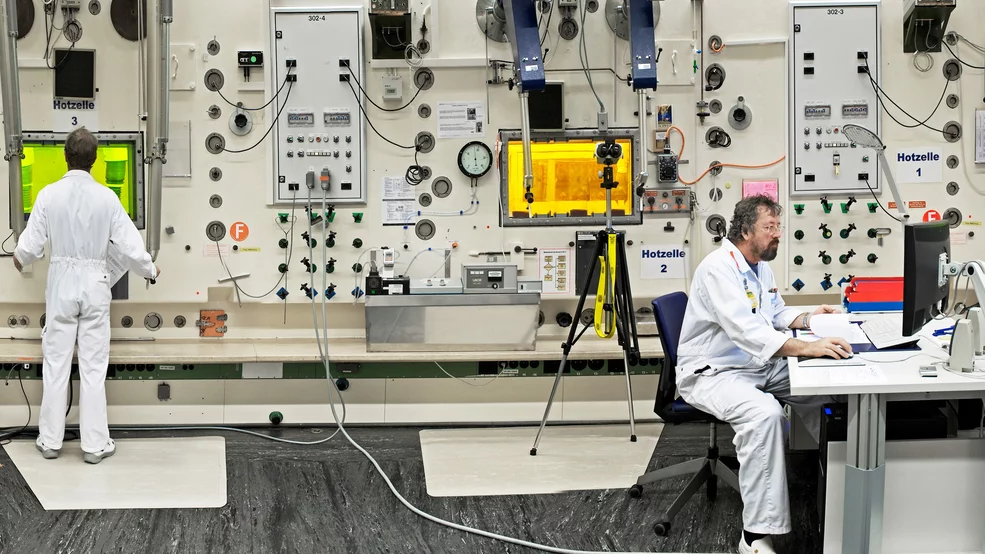

State-of-the-art methods for analysing materials allow us to peer deep inside them and identify defects or irregularities, sometimes even non-destructively. But what if the specimen to be analysed is no ordinary material, but a highly radioactive fuel rod from a nuclear reactor? In this case, an ordinary lab bench is no longer sufficient; the analysis must be conducted in a strictly protected environment – a so-called hot laboratory. The radioactive materials are manipulated by robotic arms within so-called hot cells, specialized safety zones shielded by 1.5 metres of concrete and a 90-centimetre-thick lead glass window, where their properties can be studied.

This is also what happens at PSI. For 60 years, its Hotlab has conducted complex analyses of highly radioactive materials. Such analyses help scientists understand how these materials react under the extreme conditions encountered in reactors, how they change over time and when they reach the end of their useful life. Beyond conducting fundamental research, the lab plays a critical role in maintaining-and therefore ensuring the safety of Switzerland’s nuclear facilities – and has done so from the very beginning.

A brief history of Swiss nuclear technology

The origins of the Hotlab date back to 1955, when the first conference on nuclear energy was held in Geneva under the auspices of the United Nations, aiming to harness nuclear power for peaceful purposes after its devastating effects were revealed during the war. The two-week conference provided an opportunity for more than 1,000 researchers to exchange ideas and, at the same time, heightened Switzerland’s interest in this new energy source.

Reaktor AG, founded in Würenlingen in March 1955, sought to realise this interest. Later, the federal government took over the private company and renamed it Swiss Federal Institute for Reactor Research (EIR), which eventually merged with the Swiss Institute for Nuclear Research in 1988 to become today’s Paul Scherrer Institute PSI.

Reaktor AG began planning its hot laboratory as early as 1957. Once the laboratory was completed and inaugurated in 1963, the EIR submitted its operating licence to the Federal Department of Transport and Energy on 2 November 1964, marking the official anniversary of the Hotlab.

In addition to the two test reactors, Saphir and Diorit, which were also built on today’s PSI site, the Hotlab played a central role in the development of Switzerland’s nuclear power stations. It provided researchers with the necessary infrastructure to analyse radioactive samples from reactor experiments and to advance their development–a function it continues to fulfil to this day.

Originally, the Hotlab also produced isotopes-radioactive materials essential for fundamental research as well as for radiopharmaceuticals used in tumour treatment. However, this area was spun off from the Hotlab back in the 1970s and is now a separate research division within PSI. The Hotlab also conducts research into the safe disposal and long-term storage of radioactive waste. Additionally, the radioactive waste generated during experiments is processed, stored, and disposed of on-site.

Unrivalled infrastructure

The Hotlab is located in a sealed off area accessible only through a system of security doors. Concrete and lead walls, several metres thick, protect the people working there from the hazardous radiation. “When there is no highly radioactive material in the laboratory, we encounter a somewhat paradoxical situation where our equipment detects lower radiation levels than outside, where we are exposed to natural background radiation,” explains Marco Streit, head of the Hot Laboratory Department at PSI. “This demonstrates the remarkable effectiveness of the protection provided by our walls.”

The outer walls provide only secondary protection; they are designed to prevent radioactive material from escaping in the event of an accident. The actual work on the highly radioactive fuel rods takes place within so-called hot cells, situated behind concrete walls that are 1.5 metres thick. The fuel rods, which can be up to four metres long, are delivered to these hot cells through a system of airlocks. They undergo preliminary examination before being segmented and transferred to smaller, lead-shielded cells for further analysis.

This work is done “by hand”, so to speak. “But only indirectly,” adds Streit. “Such highly radioactive substances can only be handled using mechanical grippers, operated remotely by our staff from outside the cell.” In some cases, the operators must handle tiny samples, no larger than a millimetre, where dropping anything is absolutely not an option. “Our operators have to be extremely dexterous – without actually using their hands.”

The cell can be viewed through a small window made of three thirty-centimetre-thick panes of lead glass. The characteristic green glow seen through it is not in fact caused by radioactivity but rather by the light source and the optical properties of the glass. “It would be impossible to use a neon tube or LEDs inside the cell,” explains Streit. “The intense radiation would destroy them almost immediately. This is why we use mercury vapour lamps, which have no plastic components or complex electronics, allowing them to withstand the radiation. Viewed through the thick lead glass, their light appears green.”

Withstanding radiation

Aside from the light source, everything introduced into the hot cell must also be radiation-resistant. “For example, we use a custom-designed circular saw to cut the fuel rods,” explains Streit. “Today’s commercially available saws are far too delicate and would become unusable after just a few rods.” The issue, once again, lies in the many plastic components and sensitive electronics found in modern devices.

The extreme radiation levels are also the primary reason why samples are still manipulated “by hand” using grippers. “Robotic arms, like those used in modern surgery, would certainly make the work easier, and some members of the hot laboratory community have advocated for them,” says Streit. “However, for such robots to function in these extreme conditions, all cables, processors, and circuit boards would require extensive radiation shielding – an effort that demands substantial resources.”

The analytical equipment used to examine materials in the hot cells requires similar protection: “In principle, we use the same type of equipment as in conventional materials analysis – the difference being that ours is extensively shielded so as not to be damaged by the materials it is analysing.”

Marco Streit and his team can draw on a range of different methods for non-destructively examining the surface of fuel rods within the hot cells. However, destructive techniques, where the sample must first be segmented, such as mass spectroscopy, to determine its chemical composition, can also be performed under radiation-resistant conditions in the Hotlab. Since 2021, the researchers have also been able to use a shielded scanning electron microscope with a focussed ion beam. “We use it to cut micro- or nanometre-sized samples from the highly radioactive materials. Since these tiny samples hardly emit any radiation, we can safely analyse them at the Swiss Light Source SLS or the Swiss Spallation Neutron Source SINQ using advanced imaging techniques,” says the head of the laboratory.

The future of the Hotlab

With its advanced analytical methods and complex infrastructure, the Hotlab provides conditions for the safe, detailed analysis of highly radioactive materials that are unmatched by any other facility in Switzerland, and it is highly regarded in the European and global community. Over its 60 years of operation, the laboratory has been continuously modernised and adapted to meet increasingly stringent safety standards.

The exact role the laboratory will play in the future of Switzerland’s nuclear technology is still uncertain. However, for Marco Streit, one thing is clear: The Hotlab will continue contributing for the next 30 years and beyond. “As long as nuclear power plants are operating in Switzerland, there will be a hot laboratory – if only to ensure their safety,” says Streit. “But even after that, this kind of infrastructure will be crucial when it comes to the dismantling and the long-term disposal of materials, as this is the only place where these hazardous substances can be studied safely and precisely.”